Crafting premium knitwear with 100% cotton and Shima Seiki technology since 2017.

We source premium 100% cotton yarn from RSWM Mills, maintaining a stock of 7.5 tons in 36 Pantone colors. Each batch is carefully selected for softness, durability, and sustainability, ensuring the foundation of our knitwear is of the highest quality.

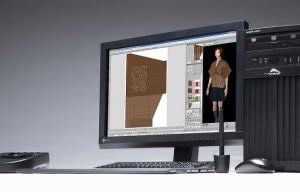

Our design team uses Apex 4 software to create intricate patterns and styles, from classic pullovers to modern custom designs. This step ensures every piece reflects innovation and aligns with the latest fashion trends.

Using 10 advanced Shima Seiki machines and 6 handflat units, our team of 50+ artisans crafts 400 pieces daily. This process combines technology and skilled craftsmanship to produce knitwear with precision and excellence.

After knitting, each piece undergoes stitching and finishing processes, including washing and steaming, to enhance softness and fit. This step ensures our knitwear is comfortable and ready for the final quality check.

Our team of 10+ inspectors conducts rigorous quality checks on every garment, ensuring flawless stitching, softness, and durability. Only pieces that meet our high standards are packed and shipped to our clients.